Transverse Horizontal Axis Water Turbine | THAWT | Modern Tidal Energy | Most Efficient Wind Turbine

Tidal Energy:

Tidal power is one such developing technology, which harnesses the kinetic and gravitational potential energy in tidal streams. When compared to other renewable sources, tidal streams are a relatively reliable source of energy, as tidal movements can be accurately predicted in terms of direction, timing and magnitude. The rapid development of devices for tidal energy exploitation is being encouraged by government initiatives and by private investment.

The horizontal axis, axial-flow turbine is the most common design of a tidal stream turbine. A number of variants of this type of device, which incorporate features such as flow-guiding shrouds or specific mounting techniques, have been proposed by different developers, but the underlying hydrodynamics remain similar for these devices. However, a drawback with such designs is that their size cannot be increased significantly, because the limited depth of flow at most sites restricts their diameter. Tidal stream energy is likely to be more expensive than either other renewable resources or combined cycle gas turbines, until at least hundreds of megawatts capacity is installed.

How Does a Free Flow Underwater Turbine Work?

Very simply, it works like a wind turbine, but the blades are moved by a water current instead of by the wind.

Transverse Horizontal Axis Water Turbine (THAWT):

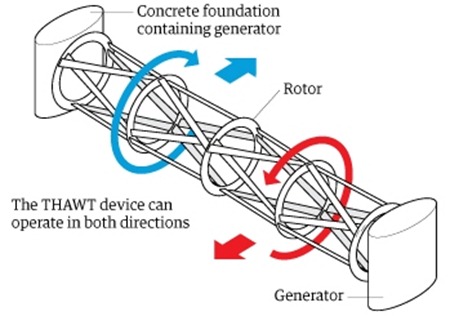

The Transverse Horizontal Axis Water Turbine (THAWT) has been proposed as a tidal device which can be easily scaled and requires fewer foundations, bearings seals and generators than a more conventional axial-flow device. The THAWT device is a horizontally deployed variant of the Darrieus cross-flow turbine, in which the blades can be oriented into a truss configuration to produce long, stiff multi-bay rotors.

A fluid particle passing through a Darrieus cross-flow turbine encounters two sets of blades. One on the front side of the turbine as the fluid enters, and again on the rear side as it leaves.

This increased stiffness and strength allows longer units to be constructed, and reduces the overall costs of foundations, bearings, seals and generators. A full scale device might have a diameter of 10 – 20 m and would operate in a flow depth of 20 – 50 m.

The THAWT device employs a truss design of blades, which is intended to increase the rigidity of the structure, so that it can be stretched across a channel without significant increases in blade stresses.

The Thawt device is mechanically far less complicated than anything available today, meaning it would cost less to build and maintain. "The manufacturing costs are about 60% lower, the maintenance costs are about 40% lower”.

The size of thawt is not limited by the depth of water in which it is situated, and the need to intersect the largest possible area of current has been incorporated into the design. Power generation of up to 100mw could be achieved by an array of only 10 thawt devices.

For comparison, if thawt devices were extended across the same area of current as axial flow devices, thawt would require:

- Less generators,

- Less primary seals, and

- Less foundations

and consequently thawt would incur:

- Lower capital costs

- Lower maintenance costs, and

- Lower operational costs

.jpg)

0 comments :

Post a Comment